Boiler feed pumps are instrumental in the circulation of water within steam generation systems. Their primary function is to deliver heated water to the boiler, where it undergoes conversion into steam. This steam, in turn, propels turbines, which power generators for electricity production.

Boiler feed pumps are crucial for maintaining a consistent and dependable water supply to boilers under high temperatures and pressures. Their stable operation is indispensable for efficient electricity generation.

The benefits of utilizing boiler feed pumps include:

- Efficiency: These pumps are engineered for optimal performance and efficient transfer of heated water, ensuring dependable operation of the steam generation system.

- Reliability: Boiler feed pumps must operate continuously with high reliability and durability to prevent downtime in power plants.

- Regulation: Systems employing boiler feed pumps typically possess mechanisms for controlling water delivery to the boiler, enabling the maintenance of ideal conditions for steam generation.

- Fuel Savings: Effectively managing the delivery of heated water with these pumps can lead to fuel savings and enhanced efficiency in electricity generation processes.

In essence, boiler feed pump is pivotal in the electricity production process in thermal power plants, ensuring a steady supply of heated water to boilers and optimal steam generation conditions. Their performance and reliability are indispensable for power plant efficiency.

Key Design Features of Boiler Feed Pumps:

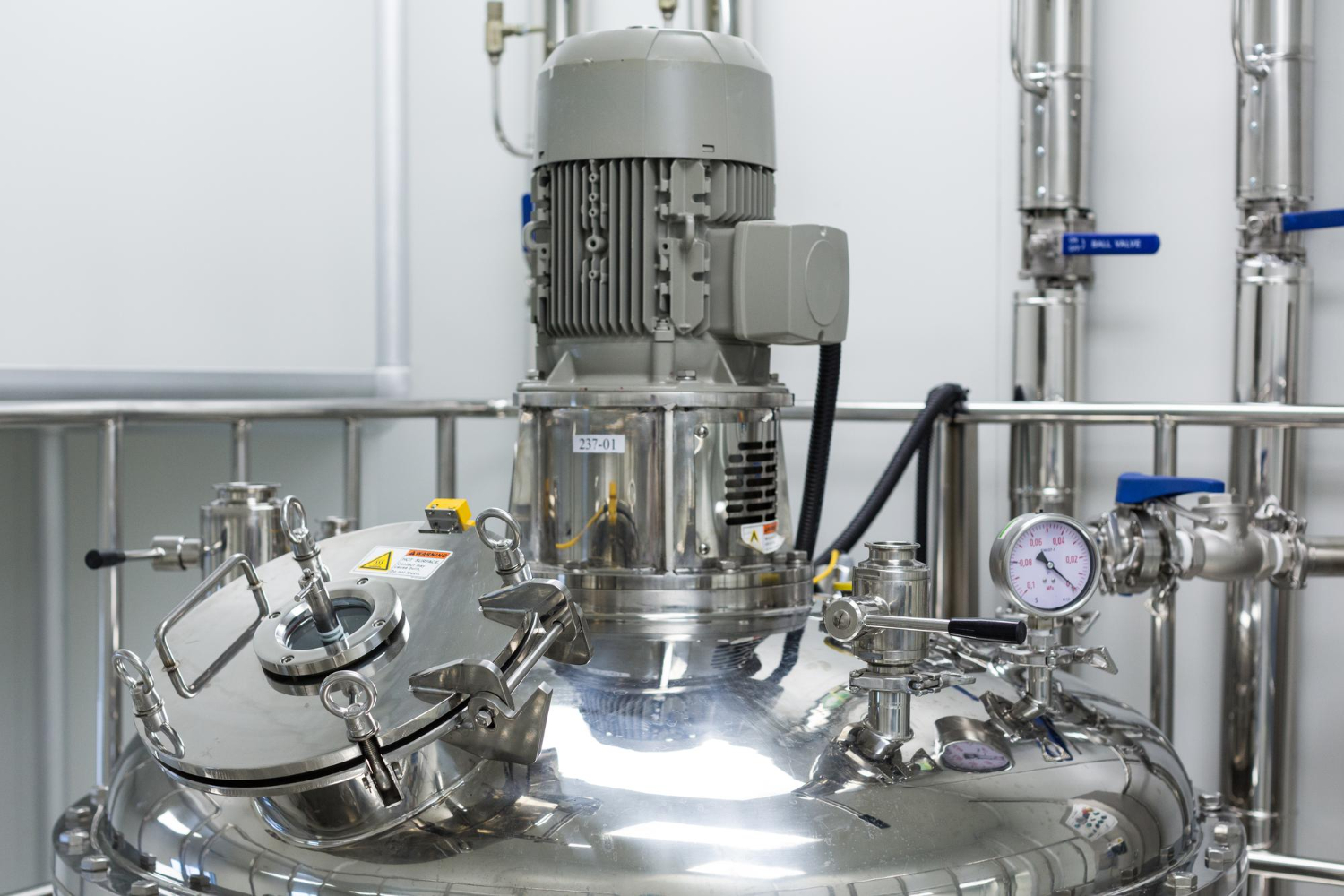

- Materials: Boiler feed pumps are commonly crafted from high-quality metals and specialized steels to withstand chemical exposure and maintain durability under extreme temperatures and pressures. Internal components like impellers and casings undergo meticulous processing to ensure effectiveness and sealing.

- Motors: Equipped with electric motors, boiler feed pumps require high power and reliable operation. Contemporary trends involve the use of high-efficiency motors with variable frequency drives for precise water delivery control and energy conservation.

- Control Systems: Modern boiler feed pumps often incorporate advanced automatic control systems to monitor and regulate pump parameters, optimizing performance and ensuring stability.

- Hydraulic Characteristics: Achieving optimal performance and efficiency entails designing boiler feed pumps to align with the hydraulic characteristics of the system they operate in, including the appropriate combination of pump element diameters and shapes.

- Monitoring and Diagnostics Systems: Contemporary pumps may feature monitoring and diagnostics systems, enabling operators to track pump condition, identify potential issues, and preempt failures.

Recent advancements in boiler feed pump design focus on enhancing wear and corrosion resistance, improving hydraulic efficiency, and reducing energy consumption. Additionally, efforts are directed toward minimizing vibrations and noise for enhanced operational comfort and prolonged pump lifespan.

Innovations in boiler feed pump design and construction also target heightened environmental sustainability, encompassing emissions reduction and optimized resource usage. Manufacturers of such pumps are actively engaged in developing new technologies and production methodologies to realize these objectives.

To summarize, boiler feed pumps are integral components of steam generation systems in thermal power plants, with their design continually evolving to ensure efficiency, reliability, and environmental sustainability in electricity generation.